- Home

- / About Us

Congue taciti consectetur duis dignissim hac placerat diam lacinia. Risus nibh auctor interdum morbi id aliquam hendrerit consectetuer.

Build Stone Prefab Wall Panels

BUILD STONE PREFAB WALL PANELS

BUILD STONE Chloride Free MgO Boards for:

Residential Buildings: Walls, flooring, ceilings

Commerical Buildings: Walls, flooring false ceilings

Industrial Buildings: Walls, flooring, roof tiles (flats & corrugated)

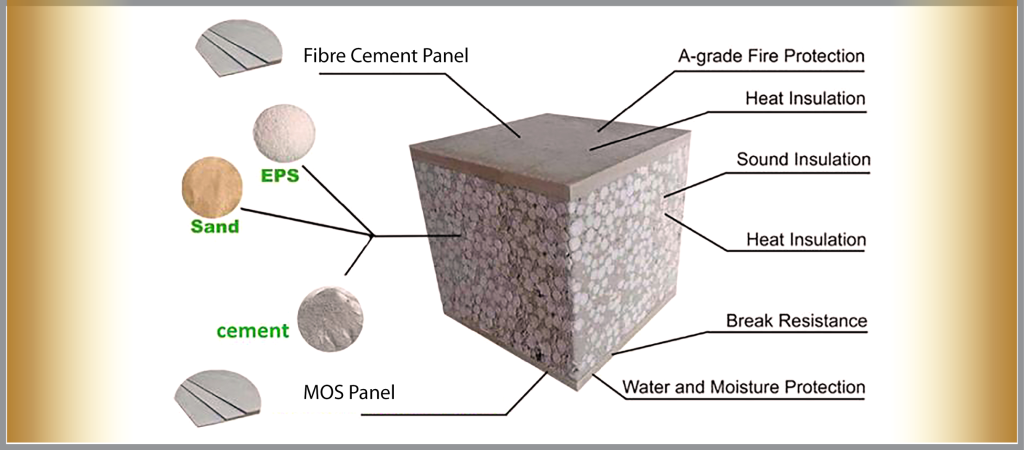

Build Stone EPS (Extruded Polystyrene) Cement Sandwich Panel is a structural insulated panel in the construction industry.

EPS wall panel is a rigid Insulating layer sandwiched between FC surface panel and MOS surface panel.

Build Stone Sandwiched EPS Prefab Wall Panel

Type |

Size |

Thickness |

Density |

Weight |

|---|---|---|---|---|

|

BBM - FC60 |

2440/3000/610 mm |

60 mm |

650-600 kg/m³ |

58 / 71 Kg |

|

BBM - FC75 |

2440/3000/610 mm |

75 mm |

650-600 kg/m³ |

73 / 89 Kg |

|

BBM - FC90 |

2440/3000/610 mm |

90 mm |

650-600 kg/m³ |

87 / 107 Kg |

|

BBM - FC100 |

2440/3000/610 mm |

100 mm |

650-600 kg/m³ |

97 / 118 Kg |

|

BBM - FC120 |

2440 / 610 mm |

120 mm |

600 kg/m³ |

107 Kg |

|

BBM - FC150 |

2440 / 610 mm |

150 mm |

550 kg/m³ |

123 Kg |

|

BBM - FC180 |

2440 / 610 mm |

180 mm |

550 kg/m3 |

147 Kg |

Sandwiched EPS Wall Panel

FC and MOS Sandwiched Surface Panels

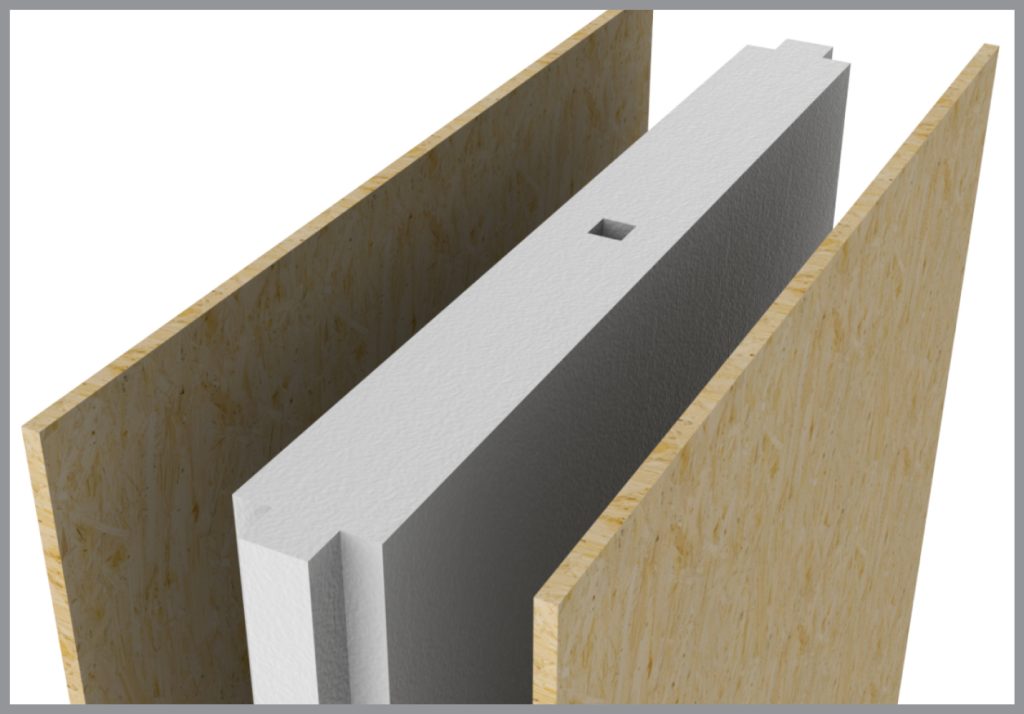

Build Stone prefabricated wall panels are steel reinforced EPS fibre cement CLC tech. They involve steel cage made with corrugated steel rods to suit the 100mm and above thick panels inserted before the slurry is poured. For smaller thick panels one layer steel cage can be used. With this reinforcement the wall panel becomes load bearing wall.

EPS Cement Sandwich Panel, also known as Extruded Polystyrene (EPS) Panel is a structural insulated panel used in the construction industry for creating partition walls. It consists of a rigid Insulating layer sandwiched between two layers of board. EPS wall panel is applied on one side FC surface panel and other side is MOS surface panel.

The structural board of the EPS Cement Sandwich Panel can either be of Magnesium Oxide Board (MgO) or Cement Fibre Board. The rigid insulation core of the EPS Panel acts as a web, while the outer boards fulfill the function of the flanges. EPS Cement sandwich panels combine several components such as studs, joists, insulation, vapor and air barrier.

With EPS cement sandwich panels being lightweight and durable, they can be used for many different interior and exterior applications such as creating partitions, foundation systems, MgO only etc.

Steel Reinforced EPS Fibre Cement CLC Tech Wall Panels

Glued Steel Fibre is a type of concrete reinforcement material manufactured by mixing straight steel Fibres with a glue compound. The glue compound used is a high-strength adhesive that is water-resistant and heat-resistant. The straight steel Fibres are usually 13 mm to 50 mm long and are added to the concrete mix to improve its mechanical properties. The Fibres are randomly distributed within the concrete to create a three-dimensional network of reinforcement, which enhances the overall durability and strength of the structure.

The glued steel Fibre has a high tensile strength, which makes it an excellent reinforcement material for concrete. The Fibre can withstand high tensile forces without breaking or deforming, which means that it can improve the structural integrity of concrete structures. The steel Fibre network created by the glued steel Fibre enhances the strength and durability of concrete, making it suitable for a wide range of applications.

Steel cage is made with corrugate steel rods to suit the100mm above panels to be inserted before the slurry is poured. For smaller thick panels one layer steel cage can be used. With this reinforcement the wall panel becomes load bearing wall.

Wall Panel Application

Internal and External walls of Residential, Commercial, Hospitals, High rise Building, Hotels, Educational Institutions.

Board Parameters | |

Heat insulated | |

Fire resistance | 2 – 4 Hours (depends on thickness) |

Moisture content | 8 – 12 % |

Water absorption | 15 % |

Thermal resistance | 0.7 m2 k/w |

Sound absorption | 42 db |

Flexural Strength | 1.74 mpa |

Compr. Strength | 6.3 mpa |

Axial Load | 37.53 kw |

Drying Shrinkage | 0.086 % |

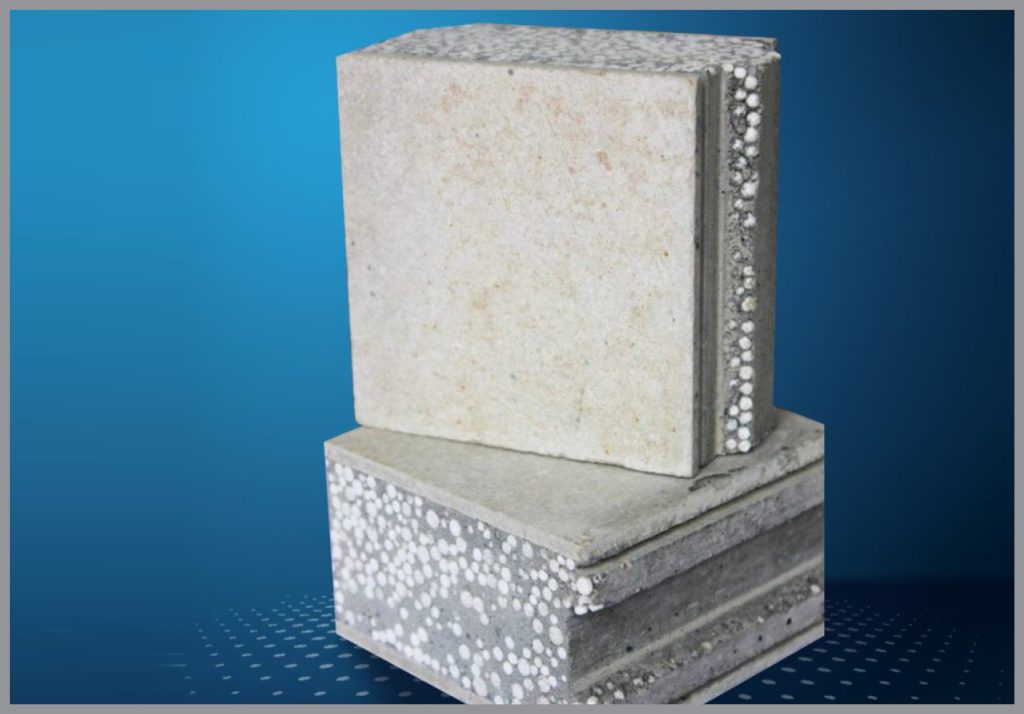

EPS Wall Panel with Fire Proof MOS Surface Panels

The production of these panels is same as FCB wall panels as described earlier, only the difference is the cement surface panels are replaced by MOS panels. The specific application is Building inner partition walls.

The dimensions and densities are approximately same as FC wall panels. But the surface looks white marble and can be coloured with varnish (pigmented), opaque. Transparent colours of choice can be given.

The advantages of MOS panels mentioned previously are applicable here too.

Advantages of Wall Panel Application

- Cost saving because of light weight

- Foundation design cost saving reducing reinforcement

- Space saving when compared to brick walls

- Time saving approximately 1/3 of conventional

- Time saving approximately 1/3 of conventional

- Fire proof, heat insulated, sound proof, water proof, moisture proof, earthquake resistant