Both sides FC Board surfaced,

EPS fiber cement cored wall panels

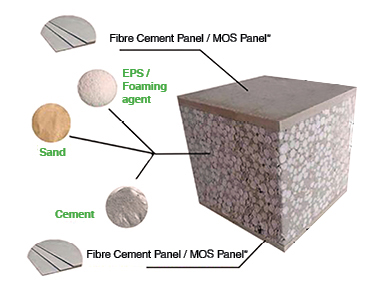

BuildStone wall panel is a sandwiched composite board formed by strong surface panel with light weight core materials

BuildStone Sandwiched EPS Prefab Wall Panel

Type |

Size |

Thickness |

Density |

Weight |

|---|---|---|---|---|

|

BBM - FC60 |

2440/3000/610 mm |

60 mm |

600-650 kg/m³ |

58 / 71 Kg |

|

BBM - FC75 |

2440/3000/610 mm |

75 mm |

600-650 kg/m³ |

73 / 89 Kg |

|

BBM - FC90 |

2440/3000/610 mm |

90 mm |

600-650 kg/m³ |

87 / 107 Kg |

|

BBM - FC100 |

2440/3000/610 mm |

100 mm |

600-650 kg/m³ |

97 / 118 Kg |

|

BBM - FC120 |

2440 / 610 mm |

120 mm |

600 kg/m³ |

107 Kg |

|

BBM - FC150 |

2440 / 610 mm |

150 mm |

550 kg/m³ |

123 Kg |

|

BBM - FC180 |

2440 / 610 mm |

180 mm |

550 kg/m³ |

147 Kg |

EPS Prefab Wall Panels can be applied for

Internal and External walls of

- Residential Buildings

- Commercial Buildings

- Hospitals

- High rise Buildings

- Hotels

- Educational Institutions

EPS Wall Panel

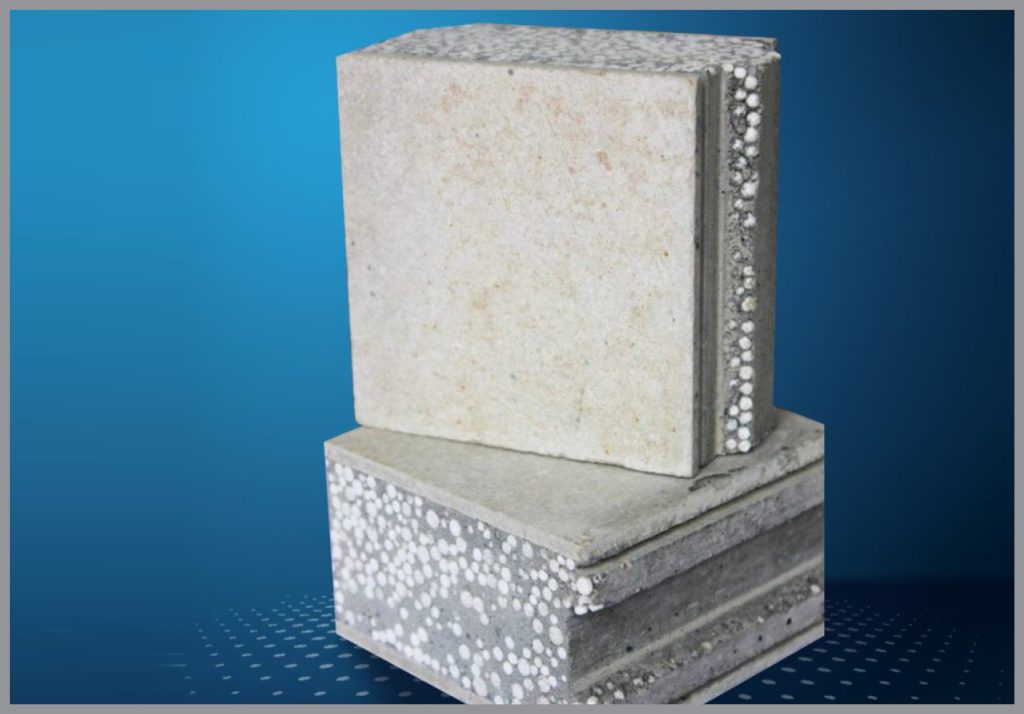

BuildStone prefabricated wall panels are steel reinforced EPS fiber cement CLC tech. They involve steel cage made with corrugated steel rods to suit the 100mm and above thick panels inserted before the slurry is poured. For smaller thick panels one layer steel cage can be used. With this reinforcement the wall panel becomes load bearing wall.

EPS Cement Sandwich Panel, also known as Extruded Polystyrene (EPS) Panel is a structural insulated panel used in the construction industry for creating partition walls. It consists of a rigid Insulating layer sandwiched between two layers of board.

The structural board of the EPS Cement Sandwich Panel can either be of Magnesium Oxide Board (MgO) or Cement Fibre Board. The rigid insulation core of the EPS Panel acts as a web, while the outer boards fulfill the function of the flanges. EPS Cement sandwich panels combine several components such as studs, joists, insulation, vapor and air barrier.

With EPS cement sandwich panels being lightweight and durable, they can be used for many different interior and exterior applications such as creating partitions, foundation systems, MgO only etc.

Wall Panel Application

Internal and External walls of Residential, Commercial, Hospitals, High rise Building, Hotels, Educational Institutions.

Board Parameters | |

Heat insulated | |

Fire resistance | 2 – 4 Hours (depends on thickness) |

Moisture content | 8 – 12 % |

Water absorption | 15 % |

Thermal resistance | 0.7 m2 k/w |

Sound absorption | 42 db |

Flexural Strength | 1.74 mpa |

Compr. Strength | 6.3 mpa |

Axial Load | 37.53 kw |

Drying Shrinkage | 0.086 % |

Advantages of Wall Panel Application

- Cost saving because of light weight

- Foundation design cost saving reducing reinforcement

- Space saving when compared to brick walls

- Time saving approximately 1/3 of conventional

- Time saving approximately 1/3 of conventional

- Fire proof, heat insulated, sound proof, water proof, moisture proof, earthquake resistant